Increase knowledge, do you know air bearings?

What is air bearing? Zhejiang Shanhai Machinery Co., LTD

Bearing, I believe that everyone is familiar with, we commonly used rolling bearings should be the most familiar, it is an important part of contemporary mechanical equipment. So what is air bearing?

Air bearing (gas bearing) : a sliding bearing using gas as a lubricant. The most commonly used gaseous lubricant is air, but nitrogen, argon, hydrogen, helium or carbon dioxide can also be used as required. In gas compressors, expanders and circulators, the working medium is often used as lubricant.

Air bearing refers to the bearing that supports the load by means of the pressure air film formed between the surfaces of the sliding pair of bearings, which is completely separated by the air film when working. Air bearing belongs to the fluid sliding bearing in the sliding bearing, working for fluid lubrication, its lubrication medium is air.

According to the formation mechanism of pressure air film, air bearings are mainly divided into two categories: aerodynamic bearings and aerostatic bearings.

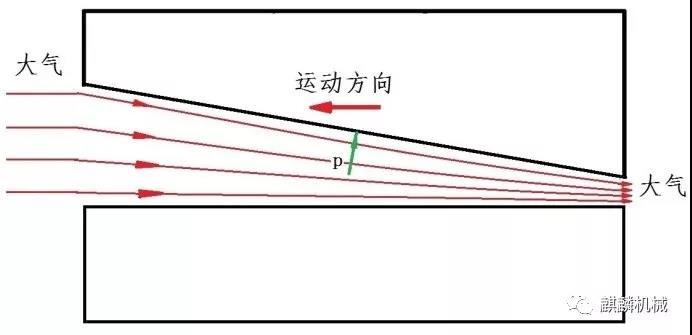

The pressure air film of the air dynamic bearing is formed by bringing air into the convergence area between the surfaces of the sliding pairs through the mutual movement of the sliding pairs. The air film is roughly wedge-shaped, as shown in Figure 1. Because aerodynamic bearings do not require an external air source, they are also called "self-acting bearings".

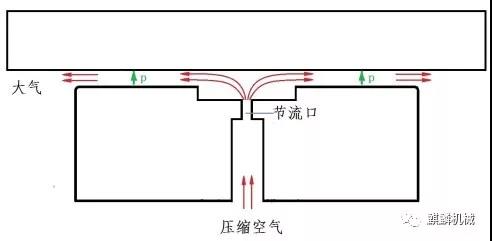

The pressure air film of the aerostatic bearing is formed by the external compressed air imported between the sliding pair surfaces through the throttle, as shown in Figure 2. Aerostatic bearings require a clean external air source.

FIG. 1 Working principle of pneumatic bearing

FIG. 2 Working principle of aerostatic bearing

Air bearing characteristics

The friction resistance is very low

Because the gas viscosity is much lower than the liquid, the air viscosity at room temperature is only 1/5000 of 10 mechanical oil, and the friction resistance of the bearing is proportional to the viscosity, so the friction resistance of the gas bearing is lower than that of the liquid lubricated bearing.

② The applicable speed range is large

Gas bearings have low friction resistance and low temperature rise. When the rotational speed is as high as 50,000 RPM, the temperature rise is no more than 20 ~ 30℃, and the rotational speed is even as high as 1.3 million RPM. Aerostatic bearings can also be used at very low speeds or even zero speeds.

③ Wide range of applicable temperature

Gas can remain gaseous in a wide temperature range, and its viscosity is very little affected by temperature (the viscosity also increases slightly when the temperature rises, such as from 20℃ to 100℃, air viscosity increases by 23%). Therefore, the applicable temperature range of gas bearings can be up to -265℃ to 1650℃.

The carrying capacity is low

The bearing capacity of dynamic pressure bearings is proportional to viscosity, and the bearing capacity of gas dynamic pressure bearings is only a few thousandths of that of liquid dynamic pressure bearings of the same size. Due to the compressibility of gas, the bearing capacity of gas dynamic pressure bearings is limited. Generally, the load per unit projected area can only be added to 0.36 mpa.

(5) High processing accuracy requirements

In order to improve the bearing capacity and film stiffness of gas bearings, smaller bearing clearances (less than 0.015 mm) than liquid lubricated bearings are usually used, and the accuracy of parts needs to be improved accordingly.

The application of air bearings

Air bearing is a new type of bearing which uses the elastic potential energy of air as support. The lubricant used is air; Therefore, air bearing technology is ideal for the workpiece or working environment that must be pollution-free.

In air bearings, the ball is replaced by an air cushion. One of the best-known applications of air bearings is perhaps the hovercraft.

Huge fans blow air under the hovercraft, preventing it from escaping through elastic rubber "skirts". The high air pressure created underneath the hovercraft supports the weight of the hull, thus allowing it to float on the air cushion.

Since the 1950s, gas bearings have been more and more widely used, and have been widely and deeply studied. At present, gas bearings can be used in textile machinery, cable machinery, instrument machine tools, gyroscopes, high-speed centrifuges, dental drills, cryogenic refrigeration machines, hydrogen expanders and high-temperature gas circulators, etc.

Source: Pump - air compressor network

Disclaimer: This article is reprinted from the network, the content of the article is only for learning, communication, air compressor network to maintain a neutral view of the article. Article copyright belongs to the original author and platform. If there is infringement, please contact to delete

Zhejiang Shanhai Machinery Co., Ltd

Tel: 13905700574

Landline: 0570-8588906

0570-8588900

Email: ryan74853@163.com

Address: No. 56, Donggang Third Road, Quzhou, Zhejiang

WeChat official account